MacBook Pro: Gray Screen of Death

In this Macbook Pro data recovery case study, the client turned on their laptop one morning and the dreaded “Gray Screen of Death” popped up. This gray screen, which Apple users may be familiar with, signifies a boot error. It’s common for the gray screen to show a folder icon with a question mark, telling the user that the system directory and files needed to boot up could not be found. After receiving this grim portent, the client brought their laptop to an Apple-certified repair technician. The technician found that the hard drive inside was making a soft clicking noise. It also became very hot shortly after receiving power. After performing their own non-invasive evaluation of the hard drive, the technician directed the client to us for our Macbook Pro data recovery services.

MacBook Pro Data Recovery Case Study: Gray Screen of Death

Drive Model: Hitachi HTS545050A7E362

Drive Capacity: 500 GB

Operating System: Mac

Situation: Gray Screen of Death, soft clicking on startup, drive gets hot very quickly

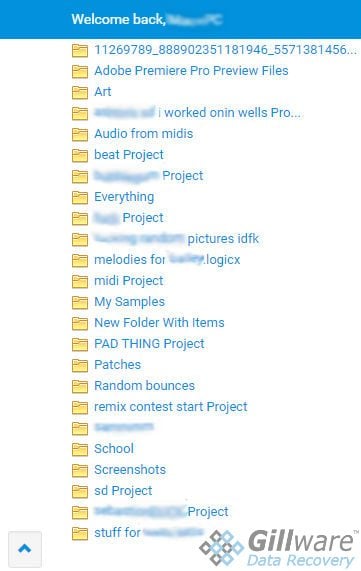

Type of Data Recovered: User documents and projects

Binary Read: 87.7%

Gillware Data Recovery Case Rating: 9

MacBook Pro Data Recovery Evaluation

The Hitachi HTS545050A7E362 hard drive’s platters spin at 5,400 revolutions per minute, or 90 revolutions per second. A spindle motor sets the platters in motion when the drive powers on, spinning the edge of the disks at around 80 miles per hour. At these speeds, one would assume the motor would produce a great deal of noise and heat. But because the spindle motor is a brushless DC motor, it is actually surprisingly quiet and heat-efficient. When a hard drive’s chassis becomes abnormally hot while running, it usually means one of two things. Either the motor has failed, or some other failed component is interfering with its normal operation. In both of these situations the likely result is that the computer won’t recognize the hard drive.

Our hard drive recovery engineers took a look at this hard drive in our cleanroom to assess its failure. The drive’s read/write heads had failed and were repeatedly making brief contact with the data storage platters, producing “dings” on the platter surfaces. When the heads were pulled away from the platters, the spindle motor spun freely and without obstruction.

There are two ways failed read/write heads can cause physical damage to a hard drive’s platters. Both cause irreversible data destruction. When the magnetic coating on a platter is damaged, it turns to dust and cannot be restored. However, one form of platter damage is less severe than the other.

Head dings happen when the heads impact the platters. They can lift up immediately afterward or clamp down on the disks’ surfaces and keep them from spinning. Individual head dings are small, usually only wiping out a handful of sectors.

Platter scratches and rotational scoring, on the other hand, happen when the heads make prolonged contact with the platters while they spin. The failed heads gouge concentric rings out of the platters’ magnetic substrate. This can destroy millions of sectors, and in severe cases make data recovery completely impossible.

In this MacBook Pro data recovery case, the platters of the hard drive had suffered moderate damage from repeated head dings.

The MacBook Pro Data Recovery Process

Work on this MacBook Pro data recovery case proceeded once the client had approved our price quote. Our first step was to have the platters burnished. Our glide burnishing tool dramatically increases our abilities to recover data from damaged platters. Nothing can actually repair the damage already done to hard drive platters. But the killer issue in data recovery isn’t always the existing damage to the platters. Rather, it is the dust that gets kicked up when the heads destroy portions of the platters.

All that dust embeds itself somewhere else on the platters. The dust isn’t the stuff you find on the top of your bookshelves. Rather, it is made up of extremely hard microparticles. These embedded particles make the platters’ surfaces very rough and bumpy on a microscopic level. This is very bad news for the read/write heads, which need a smooth surface beneath them. And so our glide burnisher smooths out the platters and buffs out those bumps to give those platters a level surface. If we couldn’t do this, any replacement heads we attempted to install would die immediately, and we would waste a lot of engineer time and effort on a fruitless data recovery effort.

After burnishing the platters, our cleanroom engineer Drew installed a new set of read/write heads. The new heads worked well for a while. They allowed us to pull about 50% of the client’s data from the drive. But eventually, they stopped working. It took another set of read/write heads to get the rest of the data off.

Adaptive Drift

Every hard drive has unique calibrations. This makes finding donor parts for failed drives a challenge. Even working parts from the same model of hard drive aren’t exactly identical. Whenever we bring a dead hard drive back to life, we have altered its baseline operating conditions to some degree. That is simply unavoidable. As its operating conditions continue to change, compatible replacement parts can cease to become compatible.

This is why an initially-compatible set of donor parts may fail before our engineers have finished pulling all of the data off. (Adaptive drift happens to healthy drives, too. But it usually happens on a much larger timescale of years, as opposed to days or hours.)

Conclusion

After two sets of read/write heads, we had successfully read 87.7% of sectors on the hard drive’s platters. There were over 125,000 bad sectors due to platter damage, preventing a perfect recovery. However, our engineers had no problem reading all of the drive’s file definitions, so we knew where all of the client’s critical data lived on the drive. Our engineers completely recovered 98.4% of the client’s documents and projects. We rated this MacBook Pro data recovery case a 9 on our ten-point data recovery case rating scale.