Hard Drive Motor Failure Data Recovery

Under normal operation, your hard drive’s platters are spinning at thousands of revolutions per minute. Modern hard drives tend to spin at 5,400 or 7,200 RPM. Enterprise-class hard drives spin at up to 15,000 RMP. The high rotational speed of your platters is what enables your hard drive to access information so quickly. A point on the edge of a 3.5-inch platter in a typical desktop hard drive can be traveling at almost 150 miles per hour!

If your hard drive’s platters have stopped spinning, your motor is seized, or if your hard drive is making a beeping, stuttering, or chattering noise, its spindle motor may have failed. This brings your hard drive to a grinding halt–sometimes quite literally–and cuts you off from all of the data you’ve stored on the drive.

If this has happened to you, though, have no fear–our data recovery technicians can help reunite you with your lost data.

Motor failed on your hard drive?

How Does Hard Drive Motor Failure Happen?

The high rotational speed of a hard disk’s platters generates the thin cushion of air that keeps your hard drive’s read/write heads afloat. All of this happens because the hard drive spindle motor dutifully does its job. Modern hard drive spindle motors have been designed to spin the platters far more quietly and efficiently than you’d expect.

But like most hard drive components, the spindle motor is delicate and vulnerable. A spindle motor failure can happen for several reasons. Most commonly, it is the result of physical trauma. Environmental conditions or old age can also cause the hard drive spindle motor’s lubricated bearings to dry out. Without lubrication, the heat and resistance generated by friction becomes unbearable. This quickly burns out the motor.

When the motor becomes seized, no matter how much power flows into it from the control board, it can’t make the platters spin. The motor can make a quiet buzzing sound, and the hard drive may become very hot.

Possible Causes of Hard Drive Motor Failure:

Physical Trauma

If you drop or mishandle your hard drive while it’s running, the read/write heads can clamp down on the magnetic data storage platters. Suddenly, something is holding the platters in place and preventing them from spinning. The spindle motor tries and tries to spin the platters, but there’s nothing it can do. This can also happen if you flip a hard drive over or handle it roughly while it’s running. Total spindle motor failure can quickly set in if you keep trying to run the drive.

Many modern hard drives have safety features built into them to prevent this situation. An accelerometer can detect when a hard drive has entered a state of free-fall and quickly move the read/write heads off of the platters. This can still render the hard drive inoperable. But the chances of the motor being seized and the platters holding your critical data becoming damaged is much lower.

Sudden Power Loss

When a hard drive gets powered off normally, the air cushion slowly dissipates as the platters slow to a halt. The read/write heads have ample time to move to their rest positions away from the platters. But if a hard drive suddenly loses power, the air cushion could vanish before the heads can move to safety as the platters come to an abrupt halt. The heads end up crashing onto the surfaces of the platters.

The next time you power your hard drive on, the spindle motor will try to spin the platters. But the heads have too tight a grip on them. Trying to run the drive could cause platter damage and spindle motor failure.

Old Age / Environmental Conditions

Just like most mechanical objects, hard drives motors eventually wear out. Similarly, they can last 6 months or 6 years. Hard drives exposed to flooding or high heat can experience motor failure at a quicker rate.

How Does Hard Drive Bearing Failure Happen?

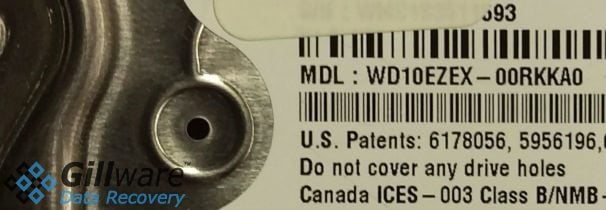

Hard drives are sealed very tightly, but they are not hermetically sealed. Most notably, they have a tiny breathing hole on the faceplate. There’s always a warning label telling you not to cover it up. But if foreign contaminants are so dangerous to a hard drive, why is there a hole there in the first place?

That hole is there to make sure the air pressure inside and outside the drive is the same. Otherwise, the hard drive’s heads might fall too close to the platters’ surfaces. Behind that hole is a cloth filter. This filter can keep all but the tiniest contaminants out. Unfortunately, even the tiniest contaminants can build up over the years and compromise the spindle motor’s lubricated bearings.

Spindle motor failure can also be brought on by environmental conditions. Exposing a hard drive to excessive humidity and heat for prolonged periods can cause the lubricated bearings to fail. If this happens, friction will overwhelm the motor and burn it out.

Why Choose Gillware for Hard Drive Motor Failure Data Recovery Services?

Recovering data from a hard drive with a failed hard drive motor can be difficult. In many cases, not only has the motor sustained damage. Motor failure can cause, or can be caused by, a domino effect of failure. Damage to the hard drive motor can come part and parcel with damaged read/write heads and damaged platters. This requires intensive cleanroom work to repair.

This intensive cleanroom work can take the form of read/write heads replacements, platter burnishing, or replacing the hard drive’s spindle motor and chassis. Occasionally, a stuck hard drive motor can be unstuck. But in cases where the hard drive motor has completely failed, the hard drive platters must be removed and placed into a compatible chassis with a functional motor. These operations are always carried out by our skilled and highly trained cleanroom data recovery technicians and engineers.